NHYTE-New Hybrid Thermoplastic Composite Aerostructures manufactured by Out of Autoclave Continuous Automated Technologies is an EU funded project that focuses on developing concepts and methodologies which will enable the realization of innovative and green integrated aero-structures made by a new recyclable hybrid thermoplastic composite material with multifunctional capabilities.

The proposed high-performing hybrid material, based on a commercial PEEK-Carbon Fiber Prepreg with addition of amorphous (PEI) films, responds to the needs for reduced weight and consequently reduced fuel consumptions and emissions of an aircraft, as well as for more ecological and less costly manufacturing processes.

Aero-structures for demonstration purposes will be fabricated by an innovative working cell implementing an advanced continuous automated production process, including:

- automated hybrid material fabrication,

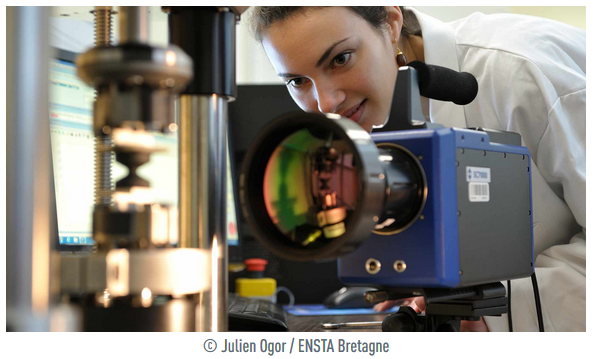

- manufacturing of skin panels by automated fiber placement in-situ consolidation process,

- fabrication of stringers by continuous forming, and

- component assembly by induction welding.

The innovative material is an example of multifunctional composite, since it returns both functions of toughness improvement (multilayer material) and process simplification. This concept on one side will provide an advantage from the structural point of view, in terms of better impact damage performance; while on the other side major advantages will result on processing simplification including improved cycle times and lower energy consumptions, since it does not require the use of an autoclave curing phase. As of today, its usage has been limited to fabricate panels, only at laboratory level; hence, a suitable improvement finalized to process in industrial environment is needed. Proposed process techniques and assembly will be the first step towards the industrial application of the innovative material.

Consortium has set a target for weight saving not less than 5% for primary structures. Further reduction of full life cycle cost is expected from scrap material and end of life structures recycling.