Research areas

- Study and optimisation of the assembly processes

- Characterisation of the long term strength of assemblies

- Development of hybrid assembly techniques for hybrid/mixed structures

ARCAN test piece glued for tensile test

Know-how

Experimental methods

Development of original experimental systems:

- for the characterisation of assemblies

- thermophysical and mechanical properties at high temperature

- thermal and electrical contact resistance

- Fine instrumentation of test pieces (micro-thermocouple up to 12 µm, field strength measurements)

Characterisation of the initial and long-term behaviour:

- behaviour of the multi-material interfacial areas

- effects of the environment (temperature, relative humidity)

- rapid characterisation methods: accelerated ageing, mass/assembly relationship, self-heating

Digital methods

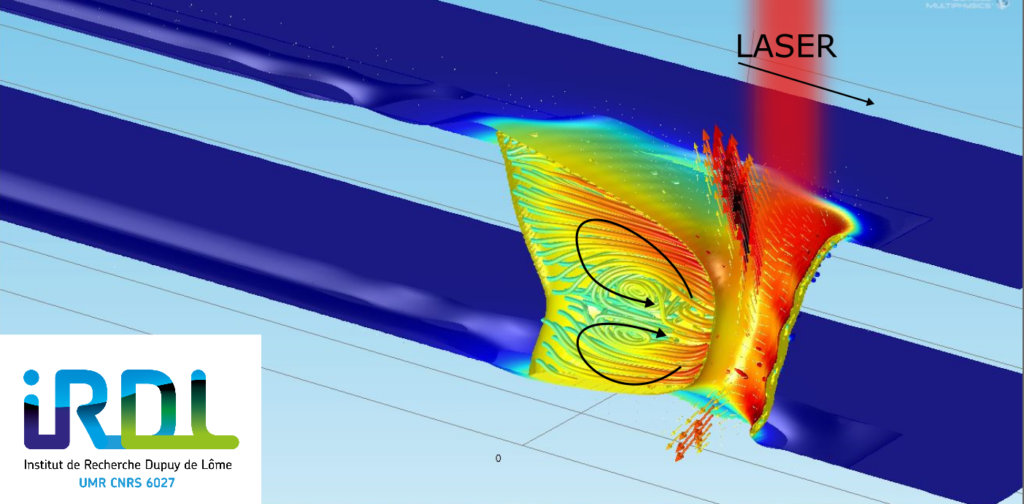

Digital simulation of assembly processes:

- digital simulation by finite elements of the assembly processes and heat treatment with dedicated software (COMSOL Multiphysics®, SYSWELD®, Forge2D®, Abaqus)

- thermo-metallurgical and thermo-mechanical behaviour in a welded assembly

- electro-thermal coupling with electrical and thermal contact resistance

- modelling of equivalent thermal sources,

- adhesive polymerisation modelling

- internal stresses in glue seals (initial state),

- magneto-thermo-hydrodynamic coupling

Digital simulation of mechanical behaviours:

- resistance and tenacity of an adhesive

- durability and ageing of glue seals

- cycling, fatigue

- Contribution of interfaces to mechanical behaviour

- Abaqus, Cast3M

Parameter and/or function estimation by inverse methods